Balcony ceiling

Product Details:

- Finish POLISHED

- Texture Customised

- Application RESIDENTIAL & COMMERCIAL

- Feature DURABILITY

- Color CUSTOMIZED

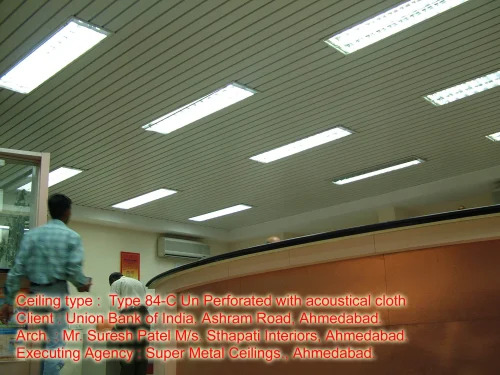

- Ceiling LINEAR CEILING

- Material GI & ALU

- Click to View more

Balcony ceiling Price And Quantity

- 150 INR/Square Foot

- 5000 Square Foot

Balcony ceiling Product Specifications

- COLOUR COATING

- SQUARE EDGE

- 12 TO 15 DAYS

- LINEAR CEILING

- POLISHED

- RESIDENTIAL & COMMERCIAL

- CUSTOMIZED

- DURABILITY

- LINEAR CEILING

- GI & ALU

- Customised

- Powder Coated / Galvanized Coated / Wooden Coated, Etc.

- 0.65 & 0.5 Millimeter (mm)

Balcony ceiling Trade Information

- Ahmedabad

- 10000 Square Foot Per Day

- 15 Days

- Yes

- Free samples are available

- BOX PACKING

Product Description

TYPES OF LINEAR CEILINGS| Type | Description | Common Materials | Ideal For |

|---|---|---|---|

| Open Cell Linear | Spaced slats allow for airflow, acoustics, lighting integration | Aluminum, steel, wood veneer | Airports, malls, lobbies |

| Closed (Flush) Linear | Slats are joined edge-to-edge, hiding mechanicals above | Aluminum, wood | Offices, corridors |

| Linear Wood Ceilings | Real wood or wood-look blades | Wood, MDF, metal with wood finish | Hospitality, boardrooms |

| Acoustic Linear Ceilings | Integrated with acoustic panels | Metal + acoustic backing | Classrooms, conference halls |

| Curved/Radiused Linear | For complex architecture and shapes | Aluminum or flexible MDF | Atriums, feature spaces |

-

Materials:

-

Aluminum (lightweight, corrosion-resistant, often powder-coated)

-

Steel (durable, good for impact zones)

-

Wood / Wood veneer / Wood-look metal

-

Perforated options for acoustics

-

-

Finishes:

-

Powder coating (RAL, custom colors)

-

Wood grain finishes (faux or real)

-

Brushed, anodized, or matte textures

-

-

Mounting Options:

-

Suspended (grid system)

-

Direct mount (for tight ceiling spaces)

-

Accessible (liftable/slidable panels)

-

-

Integration Capabilities:

-

Lighting fixtures

-

HVAC diffusers

-

Fire protection systems

-

Acoustic insulation

-

-

Airports and transit hubs

-

Hotels and luxury interiors

-

Corporate lobbies and offices

-

Auditoriums and conference rooms

-

High-end residential ceilings or soffits

Sometimes calledlinear metal ceilingsorbatten ceiling systems, these terms can overlap. Batten systems usually refer to more traditional wood/plank layouts, while linear ceilings are more modular and often metal.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese