Grid Ceiling

Product Details:

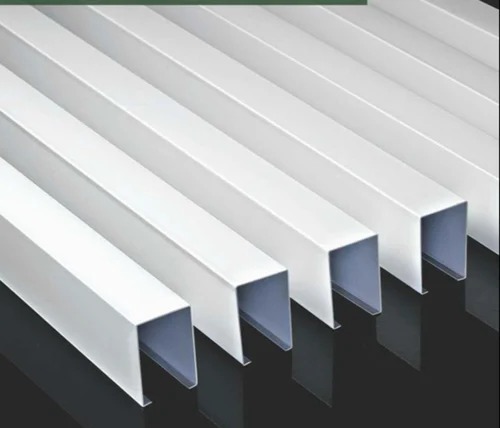

- Product Type baffle ceiling

- Pattern SQUARE EDGE

- Paint Finishing Powder Coated / Galvanized Coated / Wooden Coated, Etc.

- Feature DURABILITY

- Texture Customised

- Thickness 0.65 & 0.5 Millimeter (mm)

- Color CUSTOMIZED

- Click to View more

Grid Ceiling Price And Quantity

- 130 INR/Square Foot

- 5000 Square Foot

Grid Ceiling Product Specifications

- RESIDENTIAL & COMMERCIAL

- COLOUR COATING

- BAFFLE CEILING

- POWDER COATING

- baffle ceiling

- SQUARE EDGE

- DURABILITY

- Powder Coated / Galvanized Coated / Wooden Coated, Etc.

- Customised

- 0.65 & 0.5 Millimeter (mm)

- CUSTOMIZED

- GI & ALU

- 12 TO 15 DAYS

Grid Ceiling Trade Information

- Ahmedabad

- Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA)

- 10000 Square Foot Per Day

- 15 Days

- Yes

- Free samples are available

- BOX PACKING

Product Description

A "Baffle Ceiling" typically refers to a type of ceiling design that incorporates vertical or slanted baffles, often used for acoustical control, aesthetics, or both. Below is a short specification for a Baffle Ceiling system:

Baffle Ceiling Short Specification

System Description:

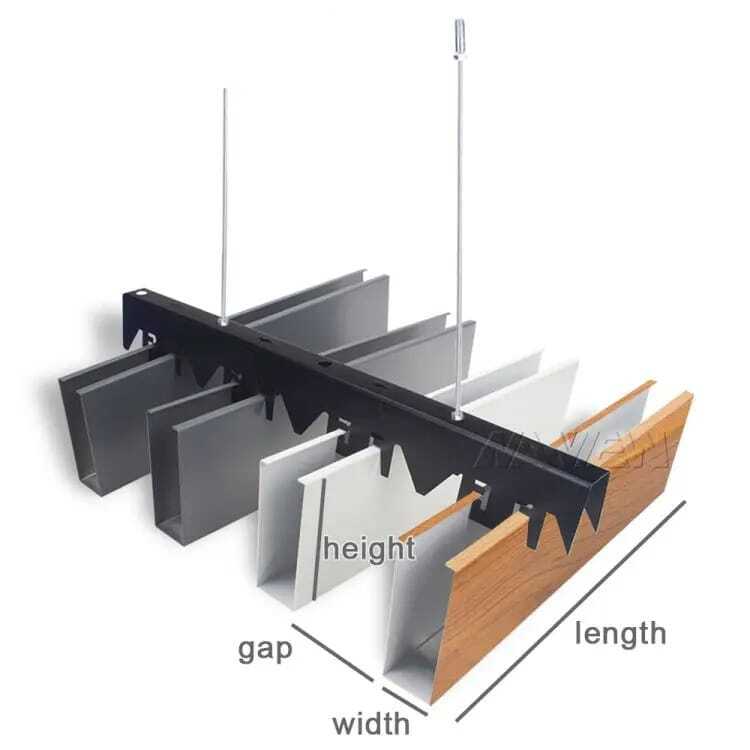

The Baffle Ceiling is an acoustical and decorative ceiling system comprising vertically or horizontally suspended baffles, designed to enhance the acoustics of a space while adding a modern, architectural aesthetic. The baffles are installed in a parallel arrangement, creating gaps between them for sound absorption and improved acoustical performance.

Materials:

-

Baffles: High-density fiberglass, mineral fiber, wood, or metal (depending on the design requirements).

-

Finish: Can be painted, laminated, or wrapped in fabric or vinyl for acoustical enhancement and aesthetic purposes.

-

Suspension System: A heavy-duty suspension system made of stainless steel, galvanized steel, or aluminum.

-

Edge Treatment: Square, beveled, or custom edges based on project requirements.

Dimensions:

-

Baffle Width: Typically 4" to 12" (can vary based on design requirements).

-

Baffle Length: Customizable, but standard lengths range from 4' to 12' or more.

-

Spacing Between Baffles: Generally ranges from 1" to 6" depending on acoustical needs.

Acoustic Properties:

-

Noise Reduction Coefficient (NRC): 0.5 to 0.95 (varies by material and finish).

-

Sound Absorption: Designed to reduce reverberation and improve room acoustics by absorbing sound energy.

-

Customization: Baffles can be tailored to meet specific acoustical standards (e.g., for classrooms, auditoriums, offices).

Installation:

-

The baffles are suspended from the ceiling grid or structure using adjustable suspension cables or brackets.

-

Installation can be configured in a linear, staggered, or random pattern, depending on the visual and acoustical design.

Maintenance:

-

Easy to clean and maintain.

-

Panels are removable for accessibility to ceiling systems (e.g., lighting, HVAC).

Applications:

-

Ideal for spaces requiring enhanced acoustics such as conference rooms, auditoriums, open office spaces, lobbies, and educational environments.

Performance:

-

Fire ratings: Class A (if using fiberglass or mineral fiber).

-

Resistant to sagging, corrosion, and other wear factors based on material selection.

This specification serves as a general guide and can be customized based on specific project requirements and manufacturer details.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese